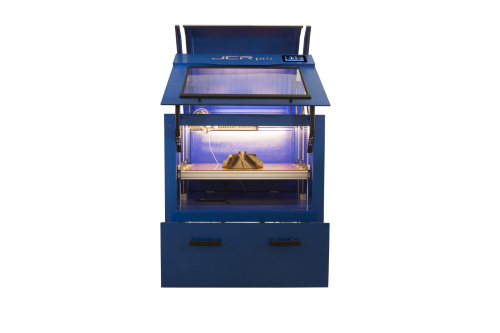

Grupo Sicnova has introduced its first 3D printer, Sicnova JCR 1000, at the 3D Printshow Madrid event. This new printing device has been developed by Grupo Sicnova’s Research & Development Lab and it’s primarily aimed to industrial and engineering applications, according to its benefits: large build volume, variety of printing materials, speed and precision.

Sicnova JCR 1000 has a large build volume of 1.000 x 600 x 600 mm (39.3 x 23.6 x 23.6 inches). It also admits many printing materials: PLA, ABS, nylon, hard rubber, PVA, PP, PC, HIPS, carbon fiber material and any material able to work with a 1.75 mm extruder and a temperature between 180ºC and 350ºC. Thus it can be considered one of the most versatile 3D printers so far, and it’s also a great choice for industries like foundry, plastic injection moulding, automotive or space industry, research labs and any professional who needs large build volumes with great accuracy levels.

The hardware assures precision up to 50 microns. There is a closed and heated environment with controlled temperature and heated bed, and also a dual 1.75mm extruder with interchangeable nozzle, high precision industrial motor controllers and an auto leveling system. Besides, the printer can manage a productive capacity of 100 cm³ per hour.

This new Grupo Sicnova’s product admits STL and G-Code files. It incorporates a Plug & Print system with file generator, and the status of the printing work can also be monitored via webcam.

Sicnova JCR 1000 can be ordered at Spanish Sicnova 3D commercial network in Spain. Additionally Grupo Sicnova is now looking for international resellers for worldwide distribution.